Manufacturing & Industrial Automation IoT Solutions

Transforming Manufacturing with Smart, Connected IoT Systems

In today’s competitive industrial landscape, efficiency, visibility, and automation are no longer optional—they are essential. Our Manufacturing & Industrial Automation IoT solutions help manufacturers modernize operations, reduce downtime, improve productivity, and gain real-time insights across the entire production lifecycle.

What We Offer

End-to-End Industrial IoT Solutions

We design, deploy, and manage secure IoT ecosystems tailored to manufacturing environments—covering hardware integration, software platforms, analytics, and automation.

Machine health monitoring

- Real-time monitoring of machine performance and condition

- Early fault detection and predictive maintenance insights

- Vibration, temperature, and energy usage tracking

- Reduced downtime and extended equipment life

- Actionable alerts and performance dashboards

VFD & motor monitoring

- Real-time monitoring of VFDs and motor performance

- Current, voltage, torque, speed, and temperature tracking

- Early fault detection and overload protection

- Energy efficiency optimization and reduced power loss

- Remote diagnostics and performance analytics

Energy consumption monitoring

- Real-time tracking of energy usage across machines and facilities

- Identification of energy waste and peak load patterns

- Cost optimization through usage analysis and demand management

- Carbon footprint reduction and sustainability insights

- Automated reports, alerts, and energy dashboards

Production line automation

- End-to-end automation of manufacturing and assembly lines

- Real-time production tracking and performance monitoring

- Improved throughput, accuracy, and product consistency

- Reduced manual intervention and operational errors

- Seamless integration with machines, sensors, and ERP/MES systems

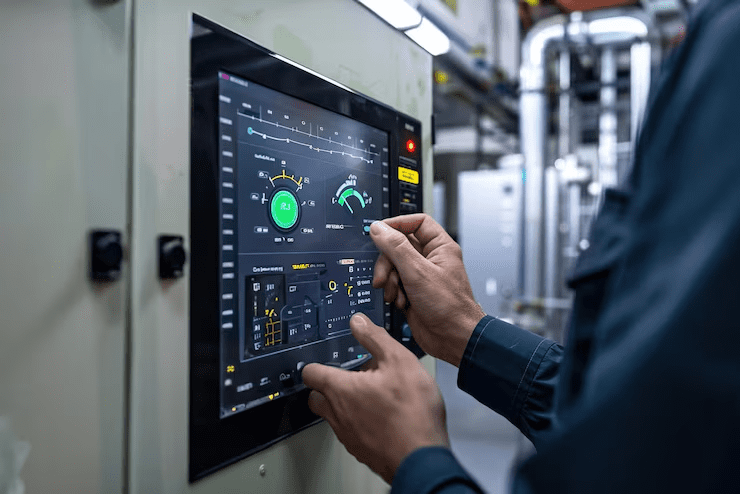

Smart factory dashboards

- Real-time visualization of production, machine, and energy data

- Centralized monitoring of factory KPIs and performance metrics

- Customizable dashboards for operators, managers, and executives

- Live alerts, trends, and predictive insights

- Improved decision-making through data-driven operations

IoT Use Cases

Smart Factory Automation

Automate production lines with real-time monitoring, automated workflows, and intelligent controls for higher efficiency and consistency.

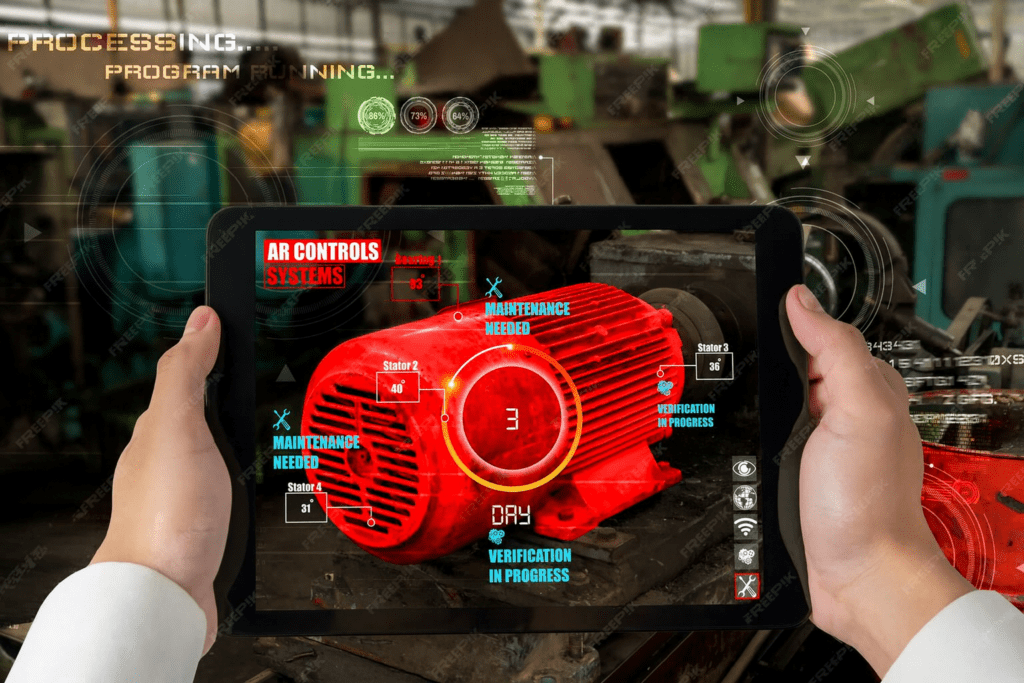

Predictive Maintenance

Detect equipment issues before failures occur by analyzing sensor data, vibration, temperature, and usage patterns—reducing downtime and maintenance costs.

Real-Time Production Monitoring

Energy & Resource Optimization

Monitor energy consumption, utilities, and raw material usage to reduce waste, cut costs, and improve sustainability.

Our Approach

1

Assessment & Strategy

Integrate sensors, machines, or smart products with ease

2

Solution Design

Architect a custom IoT system with the right sensors, connectivity, and platforms.

3

Implementation & Integration

Deploy IoT devices and integrate with existing industrial systems.

4

Analytics & Optimization

Enable dashboards, AI insights, and continuous performance optimization.

Why Choose Our Industrial IoT Solutions?

Enterprise-Grade Security

Built with robust security protocols, encrypted data transmission, and role-based access control.

Scalable & Future-Ready

Seamless Integration

Real-Time Intelligence

faq

Trusted by businesses to manage connected devices, optimize operations, and drive smarter outcomes.

What is industrial sensor & device integration?

It connects sensors, machines, PLCs, and systems to collect, transmit, and analyze real-time operational data.

Which sensors and devices can be integrated?

It connects sensors, machines, PLCs, and systems to collect, transmit, and analyze real-time operational data.

Can you integrate with existing (legacy) machines?

Which industrial protocols do you support?

Is the solution scalable for future expansion?

What business benefits can I expect?

Drive Your Smart Factory Vision Forward

Let’s build a smarter, more efficient manufacturing future together.